How the Krobo make glass beads, by Nomoda "Cedi" Djaba

This process of making glass beads was written by Nomoda "Cedi" Djaba, a bead maker from Krobo-Odumasi in Ghana. He also provided most of the photographs.

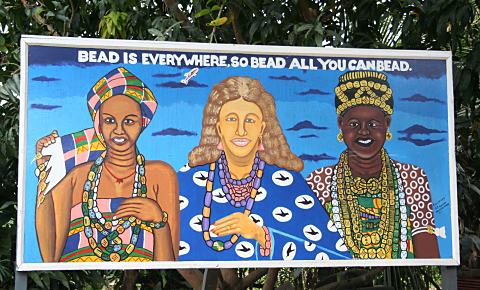

There are two main types of beads that we make in Krobo-Odumase. These are the powdered beads (Bodom, Zagba, Ader, Koli, Olongo and others) and the translucent beads. The method for making each is similar but there are differences.

The first ingredient for the beads is of course glass. Sometimes this is purchased but more often old bottles are used. The most popular are Pond's cold cream jars and Philips milk of magnesia. The interaction of the broken glass with the dyes is a prime consideration.

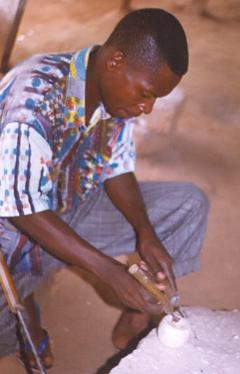

The broken bottles are washed and crushed into a fine powder. Usually a mortar and pistle are used, but sometimes a small stone is used while the glass lays in a bag resting on a large rock.

The powdered glass is then sifted using a wire mesh and a ceramic dye is added to it and stirred nicely. Clay molds are prepared by coating them with Kaolin (a white clay). Molds of various shapes are used. Some molds will hold only one large bead, others can hold a few.

A cassava stalk is inserted in the middle of the mold. When the bead, inside the mold, is fired, then the stalk will burn leaving a hole in the bead.

Next the powder is poured - very carefully - into the mold using a funnel made from a can. This is the design phase and requires the most skill. A quality bead will have a design through the whole bead, not just along the surface.

Translucent beads are made by a similar method. But the glass doesn't need to be pounded into a powder. Small particles of glass are inserted directly into the molds.

Some of the most prized beads are made by recycling older beads which are chipped.

After designing, the molds are fired in a mud kiln. The powdered beads are fired for 20 to 45 minutes at 600-850º C. Translucent beads are fired at 800-1000º C for 40 to 60 minutes. Because of this very high temperature, translucent beads can't use a stalk, so the hole must be punched by hand.

As soon as the beads are removed from the fire they are shaped with the use of two large pins.

The final step is to let the beads cool for an hour and then polish them on a stone. And then similar beads are strung on a strand.

Cedi put together this little slideshow, illustrating the process of beadmaking, back before YouTube existed. But there are lots of great videos there now! Do a search for "krobo glass" or for "nomoda djaba".

The videos at right, from Cross Cultural Collaborative, are of another glass beadmaker in Ghana.